Crover Introduces In-App Grain Moisture Sensor Calibration to Strengthen Storage Accuracy

Crover has released a new Grain Moisture Sensor Calibration flow within its Local Control App, giving operators direct control over how the robot measures moisture across different grain types.

Moisture accuracy remains one of the most critical variables in grain storage. Even small deviations can affect drying decisions, spoilage risk, and overall grain quality. While CROVER robots already provide continuous internal monitoring, field feedback made one thing clear: Users want greater control and transparency in how readings are verified, and to be able to calibrate sensors easily as and when needed. This release delivers exactly that.

How the Idea Came to Life

In real storage facilities, no two harvests are identical. Moisture can vary between wheat varieties, barley batches, and seasonal conditions. Operators often cross-check readings with handheld moisture meters to confirm accuracy before making operational decisions.

Through conversation with farmers, storage managers, and technicians, one common request kept repeating:

"Implement a way to validate a fine-tune the calibration process, without needing external support."

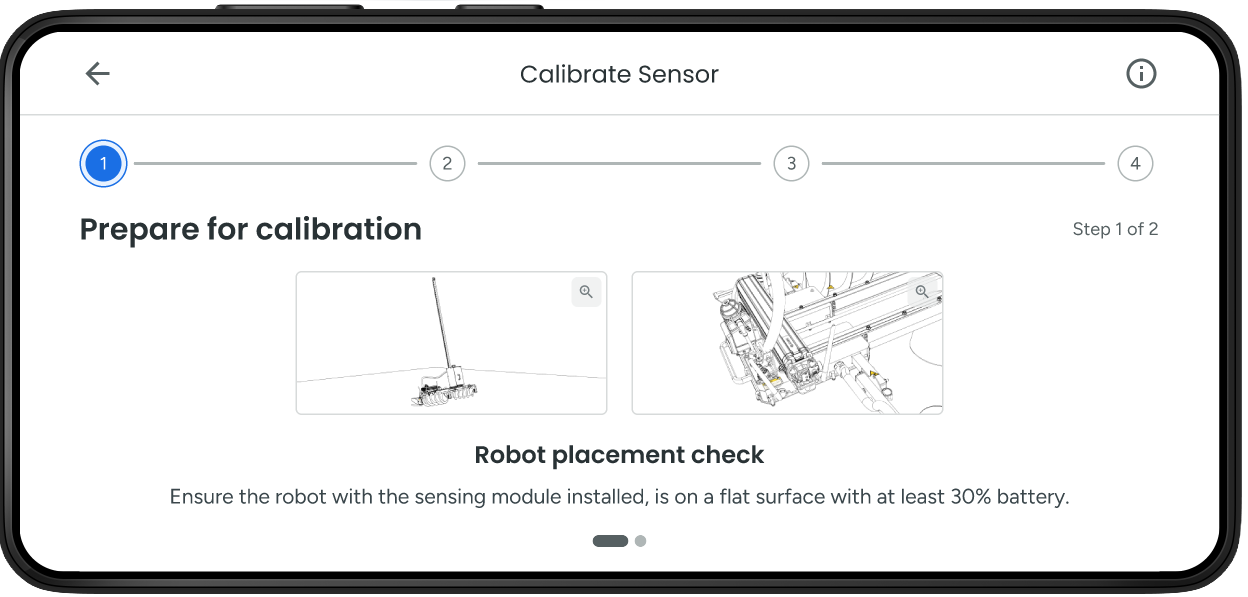

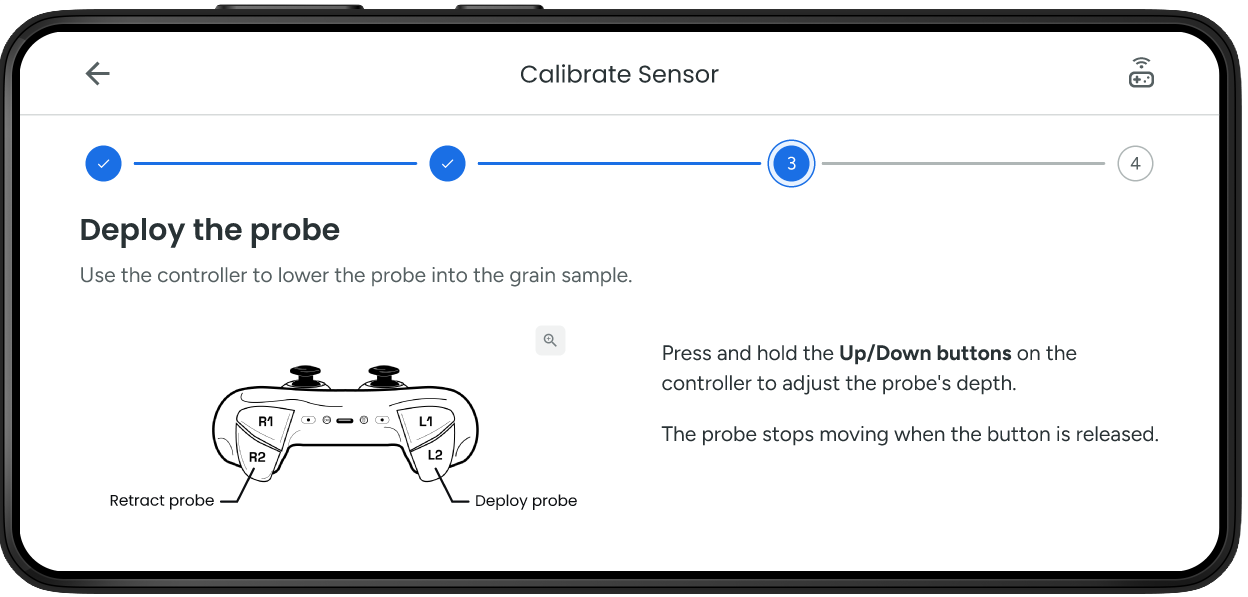

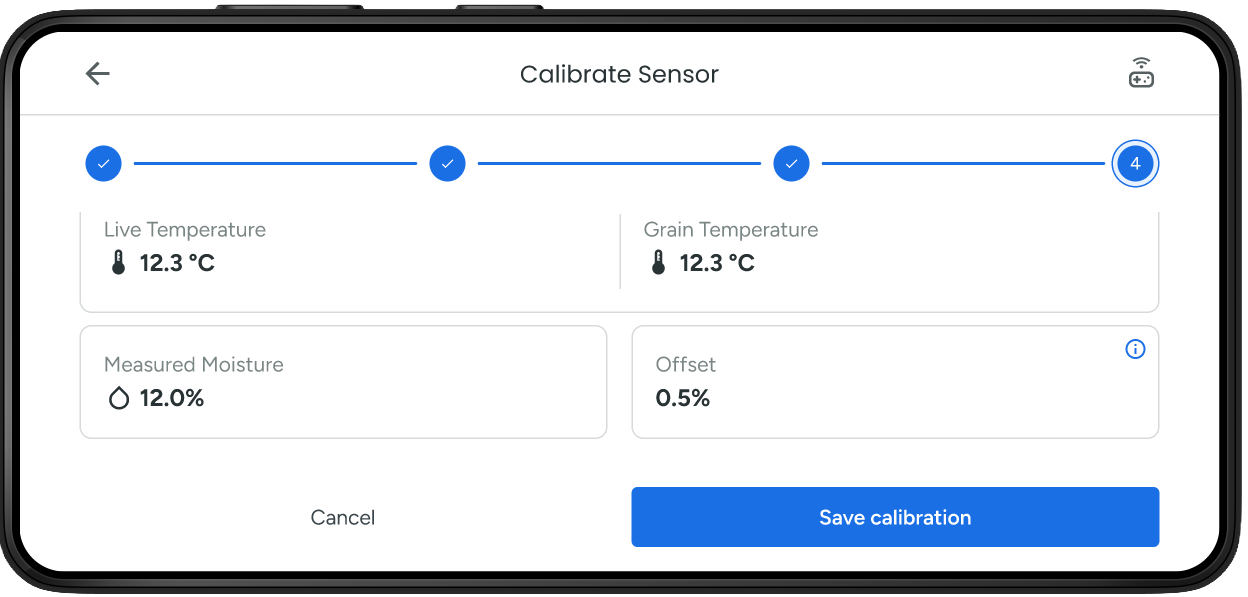

The result is a guided calibration workflow embedded directly into the CROVER robot's Local Control App. Instead of relying solely on factory settings, users can now calibrate the robot against a known grain sample, ensuring readings align with their operational standards.

What the New Calibration Flow Enables

The new feature provides:

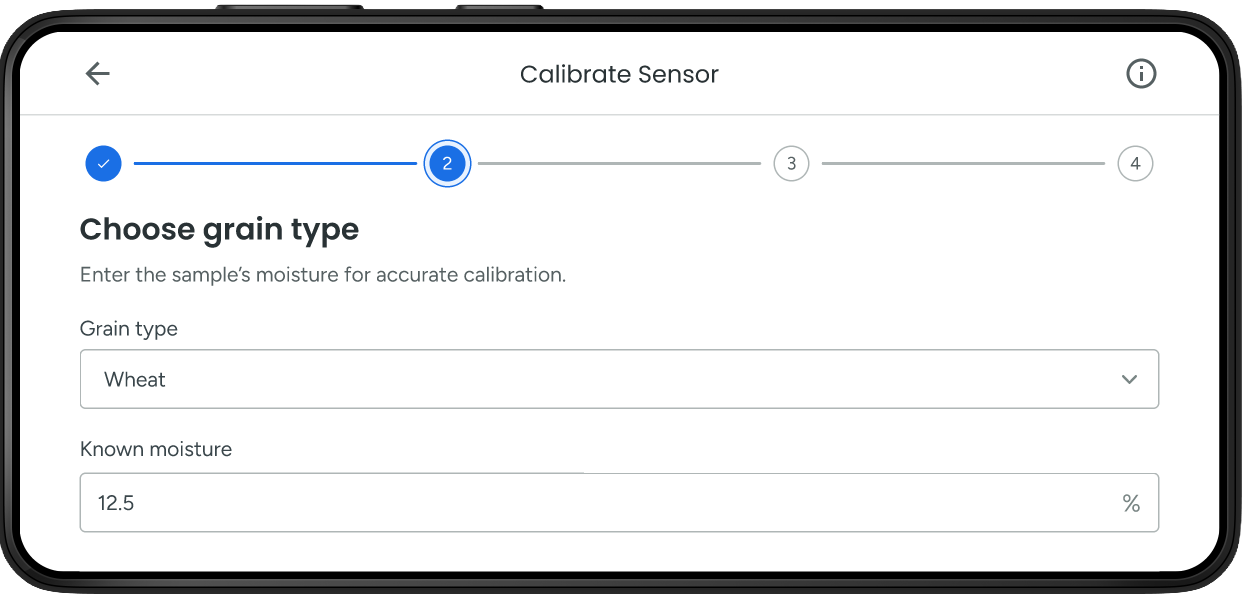

Grain-Specific Calibration

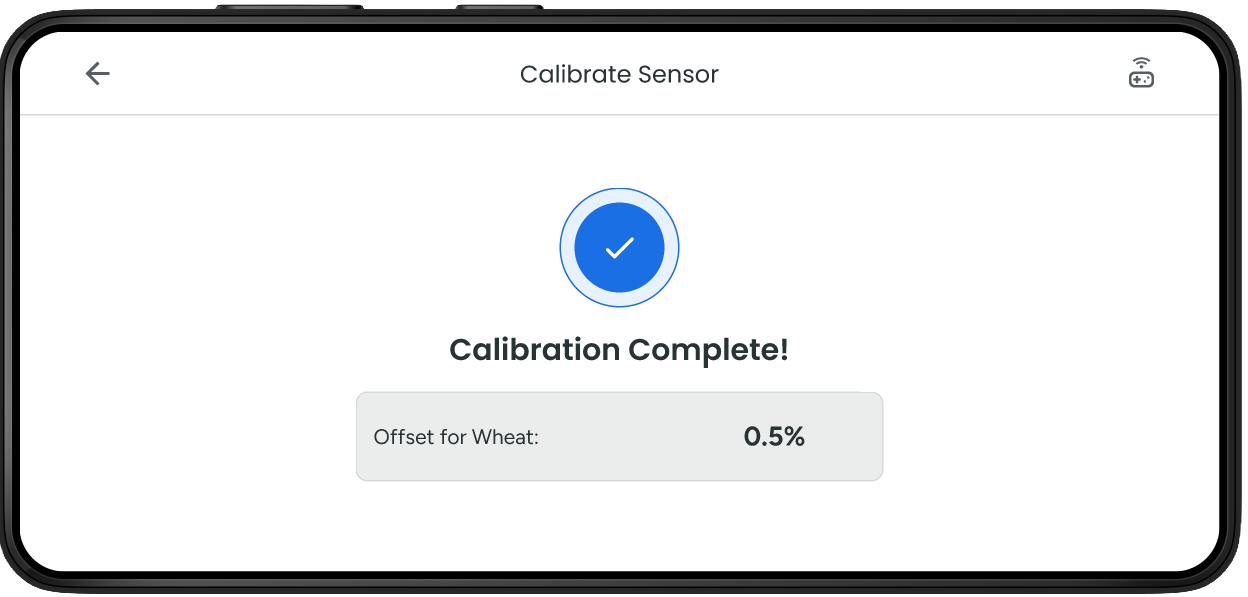

Users can select a grain type and store a dedicated calibration offset. This ensures tailored accuracy when switching between wheat, barley, or other grains.

Step-by-Step Guided Workflow

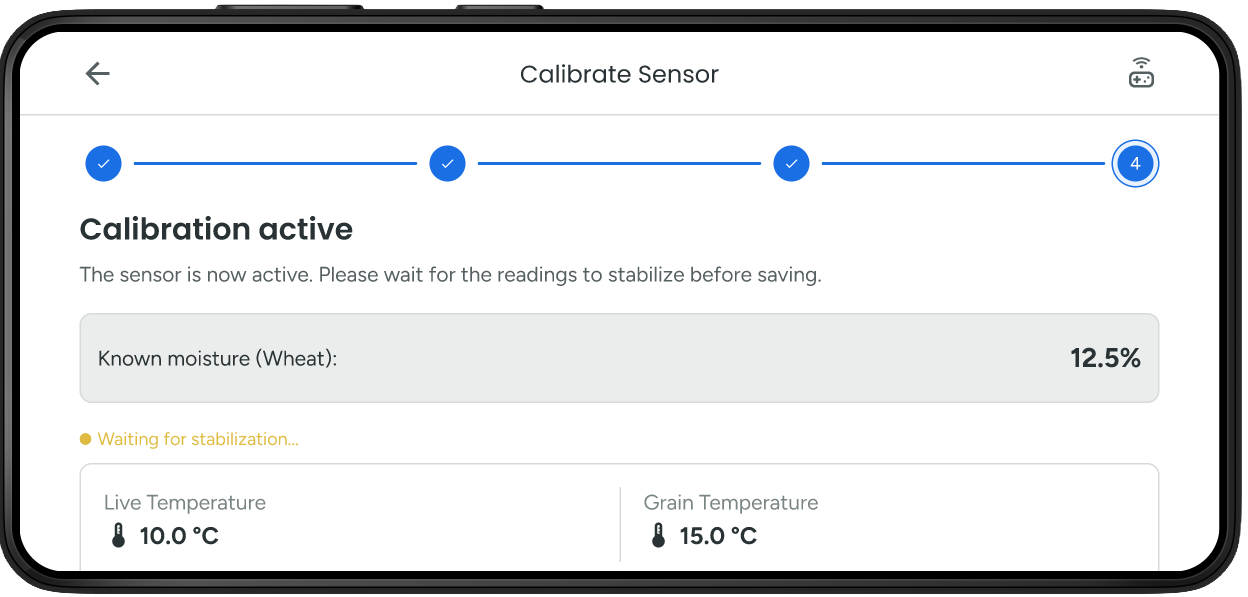

Real-Time Transparency

Live sensor data is displayed during calibration, allowing operators to see exactly how readings respond before saving.

Data Integrity Protection

Calibration updates do not overwrite historical survey data. Previous monitoring results remain unchanged.

Designed for Real-World Operations

The calibration flow supports several practical scenarios:

- Pre-season setup before new harvest storage

- Switching between grain types

- Routine maintenance checks

- Technician-led sensor validation

By integrating calibration directly into the app, CROVER aligns its system with the expectations users already have from certified grain moisture meters, while preserving the advantages of autonomous robotic monitoring.

Strengthening Trust in Autonomous Monitoring

Autonomous grain monitoring must be both intelligent and dependable. By giving users visibility and control over calibration, CROVER reinforces confidence in every moisture reading collected inside the grain bulk.

This update represents another step toward making robotic grain storage monitoring not only innovative, but professionally reliable.